- Solution

- Products

Products All Menu View

- Function

- Product/Service

- ONE AI

- OmniEsol

- Amaranth 10

- WEHAGO

- WEHAGO H

- IDC

- The Porter zone

- GEN AI DEWS

- MES

- Amaranth 10 UC

- WEHAGO T

- WEHAGO V

- Cloudserver

- Factoring

- Insight OFUS

- EFIS

- Argos EIM

- Smart A 10

- Medical Big Data Platform

- Cloudfax

- Electronic Tax Invoice

- ICS

- Argos EDM

- NAHAGO

- Certified E-Document

- Smart Works v4.0

- Local Government Digital Civic Administration Service Platform

- iCUBE

- iCUBE G20

- Bizbox Alpha

- WE Builder

- Smart A 2.0

- ERP 10

- Company

- Media

- Investors

- Solution

- Products

- Function

- Product/Service

- ONE AI

- GEN AI DEWS

- Insight OFUS

- OmniEsol

- MES

- EFIS

- ICS

- Amaranth 10

- Amaranth 10 UC

- Argos EIM

- Argos EDM

- WEHAGO

- WEHAGO T

- Smart A 10

- NAHAGO

- WEHAGO H

- WEHAGO V

- Medical Big Data Platform

- Certified E-Document

- IDC

- Cloudserver

- Cloudfax

- Smart Works v4.0

- The Porter zone

- Factoring

- Electronic Tax Invoice

- Local Government Digital Civic Administration Service Platform

- iCUBE

- iCUBE G20

- Bizbox Alpha

- WE Builder

- Smart A 2.0

- ERP 10

- Company

- Media

- Investors

- KOR

- Solution

All menu

Products

DOUZONE ICT GROUP provides ICT services that lead enterprise informatization.

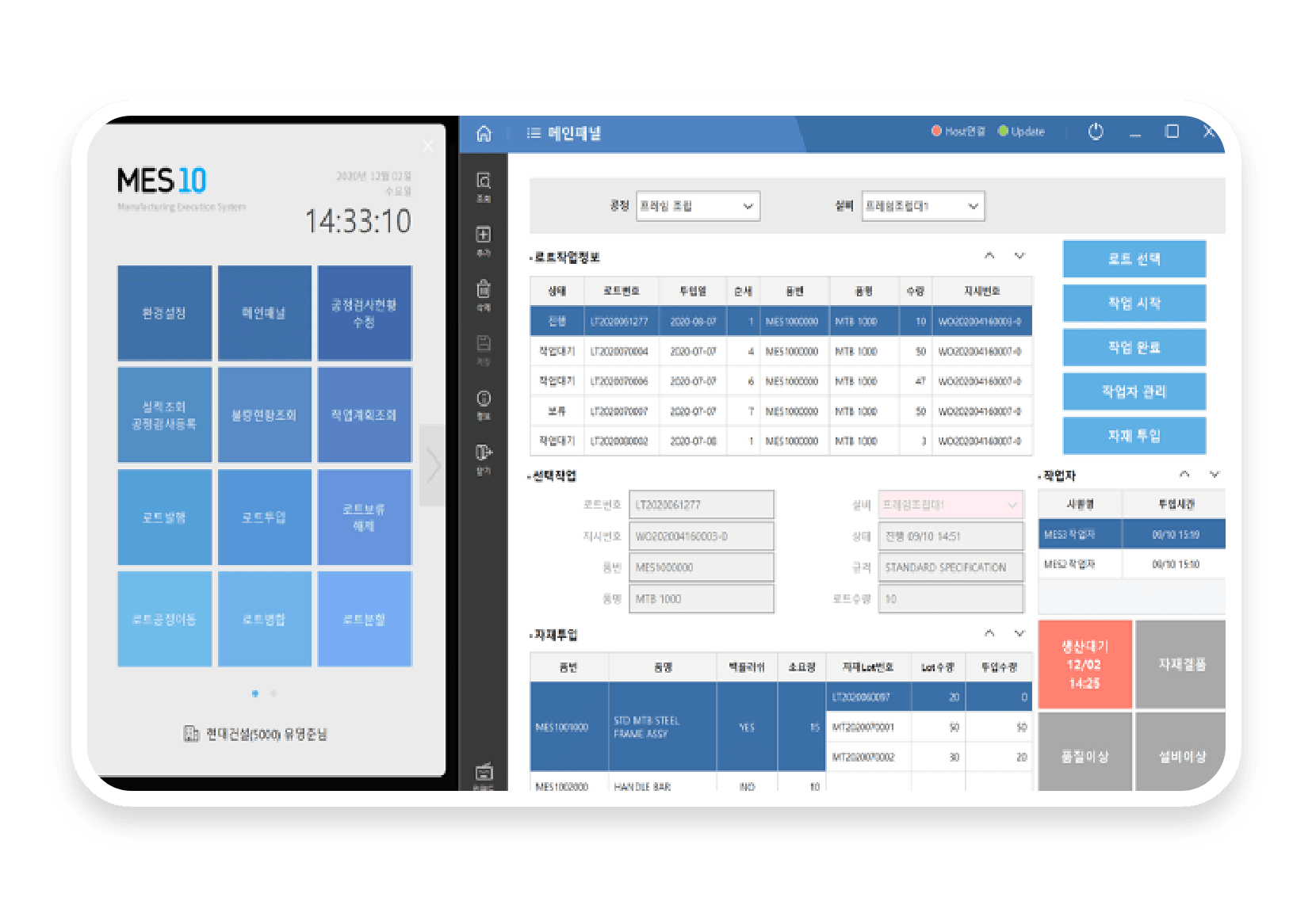

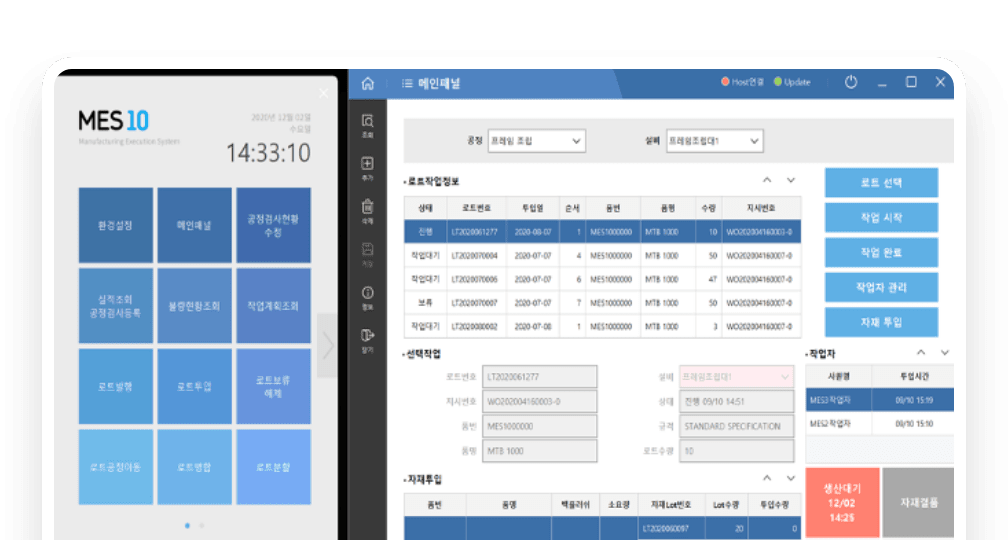

Data generated in production lines are systematically integrated and managed

to improve process efficiency and optimize the production activities.

As a core solution in building a smart factory, MES 10 provides an optimized smart factory solution step-by-step accommodating

the company's current status and capabilities based on a deep understanding in production lines and business management.

the company's current status and capabilities based on a deep understanding in production lines and business management.

MES 10 improves efficiency and optimizes production activities

provides optimized service with the deep understanding of

production lines

provides optimized service with the deep understanding of

production lines

MES 10 Baisc modules

- Basic Information

-

- Process Information

- BOM Information

- Item Information

- Activity Information

- Quality Information

- Facility Information

- Work Order

Management -

- Production Order Conversion Processing

- Work Order Confirmation

- Work Order Adjustment

- Production Order Schedule Management

- Review Work Order

- Performance

Management -

- Working Performance Entry

- Working Performance Adjustment

- Repair Performance Registry

- Defect History Review

- Materials Management

-

- Materials Lot Management

- Materials Lot Activity History

- Release Request

- Release Work Status

- Process Analysis

-

- Work Performance Analysis

- Defect Analysis

- Productivity Analysis

- Idling Analysis

- Lot Management

-

- Lot Management

- Work In Progress Status

- Lot tracing/history

- Process Data Analysis

- Manufacturing Record

Document -

- Product Standards Document

- Prepare Manufacturing Recipes

- Prepare Inspection Recipes

- Run Manufacturing Records

- Print Manufacturing Records

- Site Screen

-

- Common Menu

- JOB Process

- LOT Process

- Repair Process

- Fair Logistics

- Weighing Management

MES 10 Distinctive Advantages

Recommended for

- Manufacturing

Benefits

MES 10 supports the generation of enterprise profits driven by production line, quality improvement, work efficiency, and expected effects.

purchasing consultation

1688

5000

5000